News Story

Smaller Is Not Always Better: A New Model for Thermoelectric Materials

New research by Department of Materials Science and Engineering (MSE) graduate student Jane Cornett and her advisor, MSE and Institute for Research in Electronics and Applied Physics (IREAP) assistant professor Oded Rabin, challenges previous assumptions about the behavior of thermoelectric materials at the nanoscale, and presents a new model for predicting their efficiency and performance.

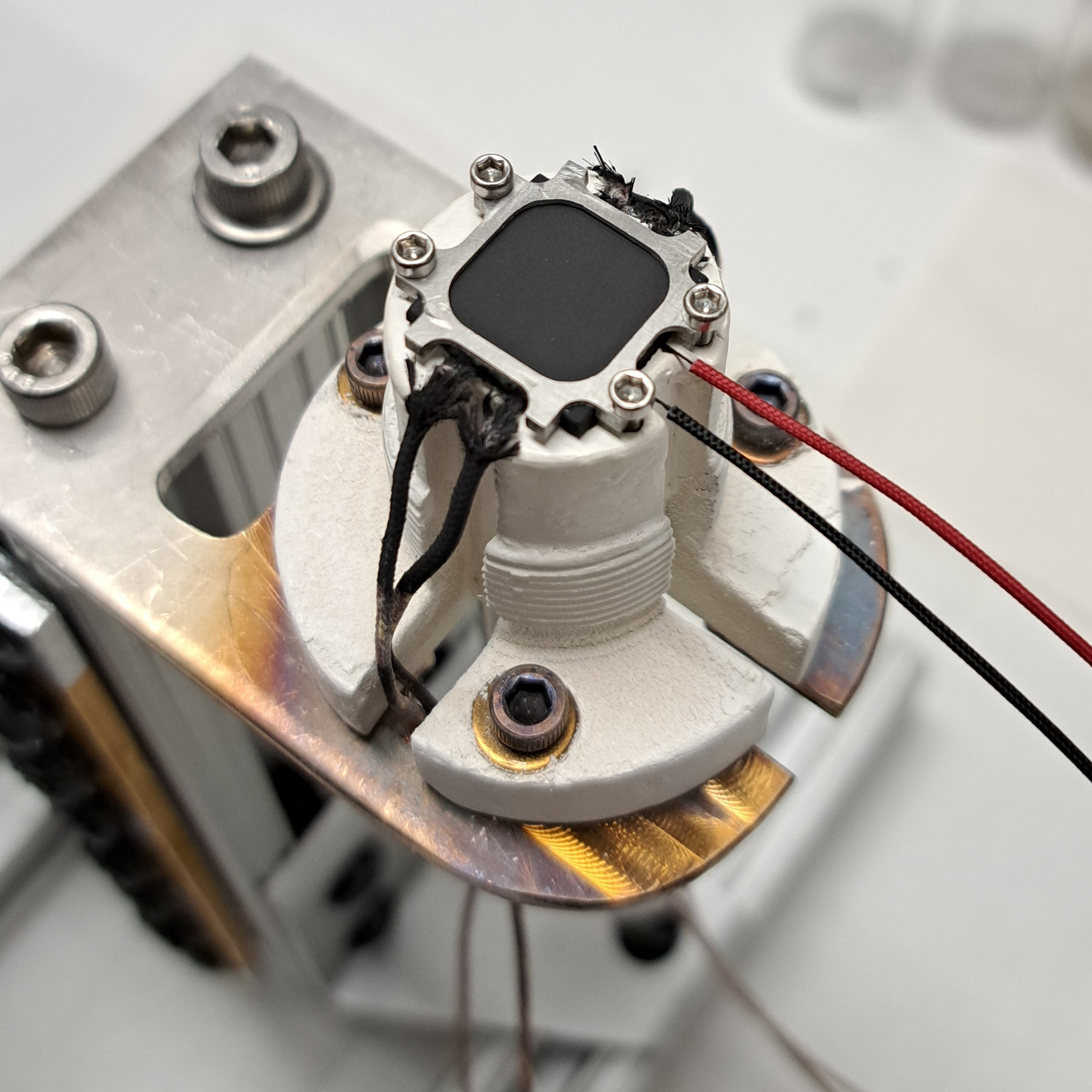

A material whose response to a change in temperature generates electric potential, or vice versa, exhibits what is known as a thermoelectric effect. Materials capable of producing the effect are currently used in a few consumer products, including refrigerators, CPU coolers in computers and thermoelectrically heated and cooled seats in luxury cars. They are more common in scientific systems, precisely regulating the temperature of lasers and imaging devices, or powering spacecraft in situations where solar panels are not an option.

The promise of thermoelectric devices is their ability to capture waste heat—which accounts for about 60% of the energy produced by the fuels we burn—and convert it into electricity or other useful forms of energy. A thermoelectric device installed in a car could use the heat coming off the engine to power the electrical systems of the vehicle. Thermoelectric devices could also allow us to discontinue the use of fluorocarbon refrigerants, giving us fluid- and compressor-free cooling systems.

So why doesn't every factory, home and car have a thermoelectric air conditioner?

"The reason thermoelectric devices have so far been limited to niche markets is that their own efficiency is still too low,"Cornett explains. "The goal of our work is to search for thermoelectric materials and systems that perform well enough to get them into widespread use."

To tackle the problem, Cornett and Rabin had to challenge some popular theories.

"Previous models told us that decreasing the size of a material to extremely small dimensions would lead to an improvement in its properties and efficiency, vs. using it in bulk," says Cornett. "The models also predicted that the smaller the nanostructure, the more significant the improvement would be. In practice, people weren't seeing the gains they thought they should when they designed thermoelectric devices with nanoscale components, which indicated to us that there might be an issue with the interpretation of the original models."

Cornett and Rabin have presented a new and improved thermoelectric model that confirms that smaller is not always better. Using advanced computer modeling to investigate the potential of thermoelectric nanowires only 100 to 1000 atoms thick (about 1000 times smaller than a human hair), they demonstrate that in the set of the tiniest nanowires, measuring 17 nanometers or less in radius, decreasing their radii does result in the increased thermoelectric performance previous models predict. In nanowires above 17 nanometers in radius, however, an improvement is seen as the radius increases.

"The surprising behavior in the larger size range demonstrates that a different physical mechanism, which was overlooked in previous models, is dominant," says Cornett.

"We believe our work is an exciting advance in the field of thermoelectrics because it resolves the previous discrepancy between theory and experiment," she adds. "With this model, we can sort through materials, structures and system sizes and identify those that will exhibit high efficiencies. Theoretical work of this kind is a crucial first step in the development of products that recycle waste heat and effectively reduce our consumption of fossil fuels."

Cornett and Rabin's research is supported in part by the Minta Martin Foundation. The work was recently published in Applied Physics Letters.

For More Information:

See "Thermoelectric figure of merit calculations for semiconducting nanowires." Jane E. Cornett and Oded Rabin. Applied Physics Letters 98(1), 182104 (2011). Abstract »

Visit Professor Rabin's Materials and Interface NanoTechnology Laboratory web site »

Published May 9, 2011