News Story

DOE Report Considers Potential of Thermoelastic Cooling

Thermoelastic cooling technology developed at the University of Maryland was reviewed in the U.S. Department of Energy’s Office of Energy Efficiency & Renewable Energy’s (DOE-EERE) Non-Vapor Compression HVAC Technology Report. The report identifies emerging alternatives to traditional heating and cooling systems, with a particular emphasis on solutions that are more affordable, efficient and environmentally friendly.

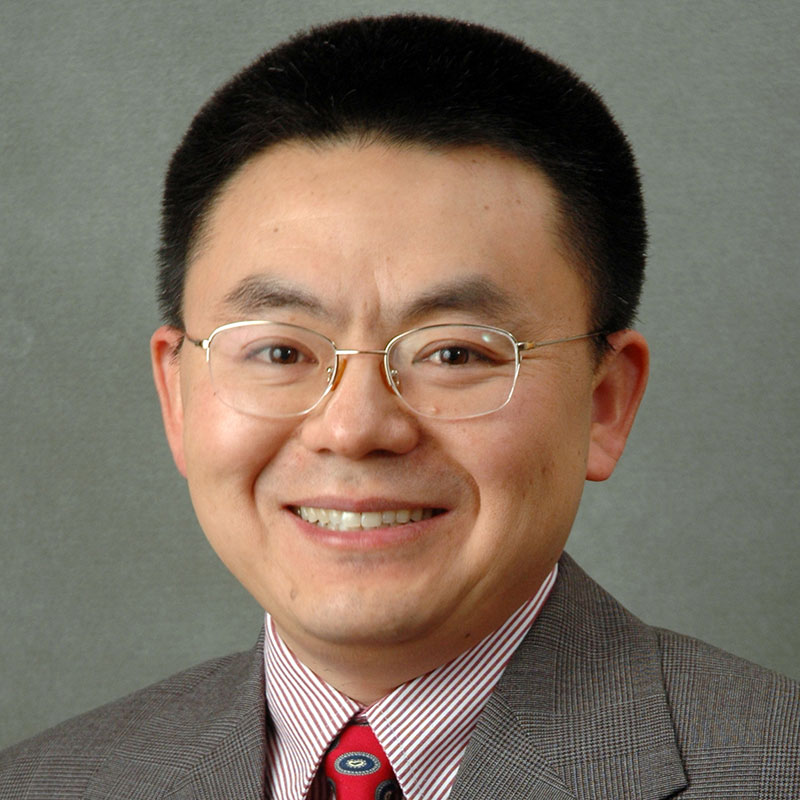

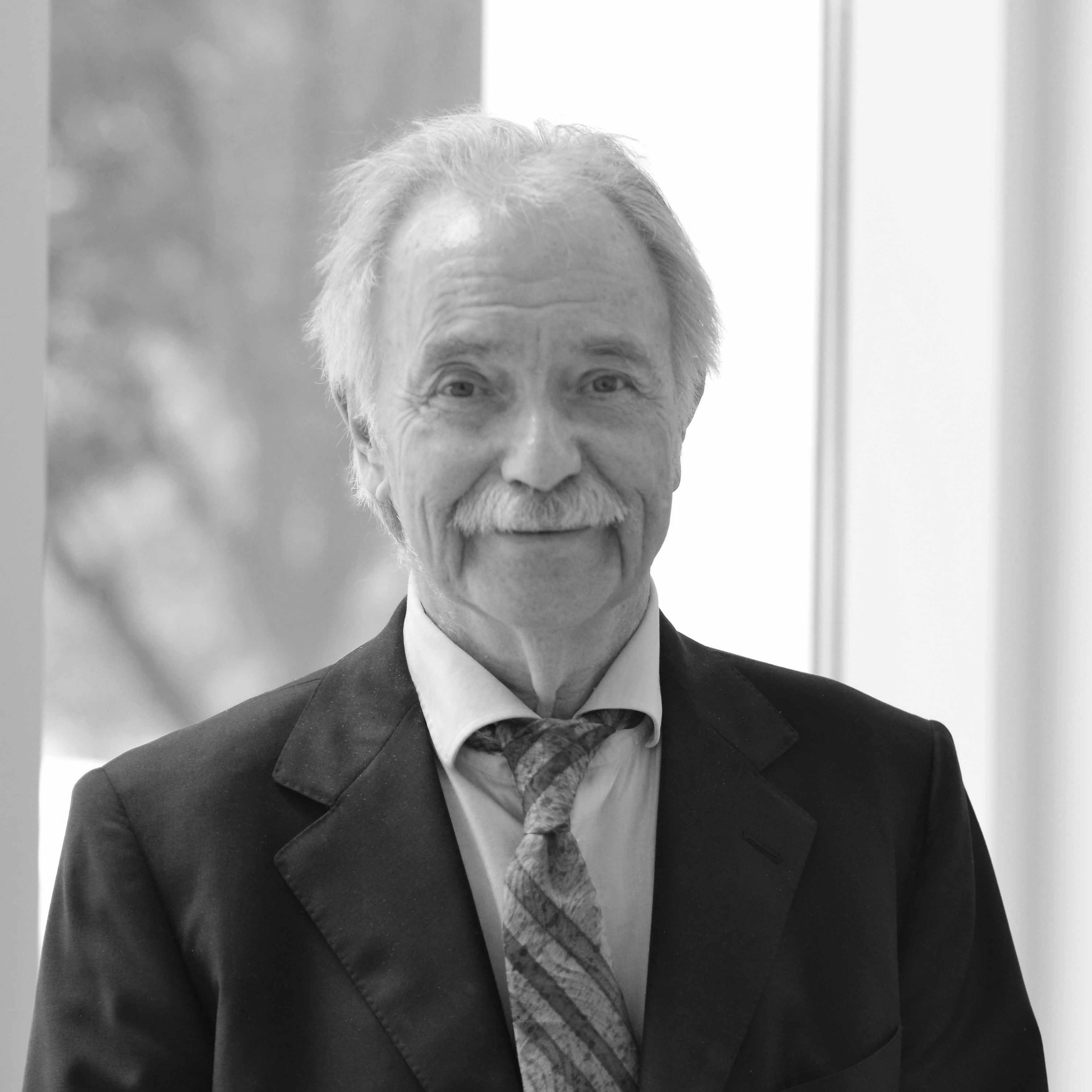

In 2010, Department of Materials Science and Engineering professors Ichiro Takeuchi and Manfred Wuttig and their colleagues designed a solid-state cooling system based on a thermoelastic shape memory alloy created in their labs. The metal creates heat when subjected to mechanical stress, but rapidly cools when released. The alternation between the two states performs the same task as the compressor found in a refrigerator or heat pump, but without the use of hydroflourocarbons and hydro flourochlorocarbons (such as Freon) that are harmful to the environment. Takeuchi and Wuttig have also used nitinol, a commercially available shape memory alloy, in their devices.

Over the past four years, the DOE’s Advanced Research Projects Agency for Energy (ARPA-E) has funded the team’s development of proof-of-concept and prototype systems. Current research goals include creating a full-scale window air conditioning unit and shape memory alloys with enhanced durability.

Backed by a federal Small Business Innovation Research (SBIR) grant, Takeuchi launched a startup company called Maryland Energy and Sensor Technologies, LLC, (MEST) to market the technology to HVAC manufacturers. MEST has also received a grant from the State of Maryland to develop a prototype air conditioning system for cars.

The DOE-EERE’s full report is available for download in PDF format:

“Energy Savings Potential and RD&D Opportunities for Non-Vapor-Compression HVAC Technologies.”

Published June 13, 2014